Industrial Visit

| Name of the Event: | Visit at Bhandup Water Treatment Plant |

| Date & Time : | 2nd April 2025 |

| Venue : | Bhandup Water Treatment Plant, Khindipada, Bhandup (West), Mumbai, Maharashtra – 400078 |

| No. of Participants : | 20 |

| Platform/Mode : | Offline |

| Faculty In-charge : | Mr. Pushkar Bharambe (Asst. Prof.) |

Summary of the Event :

A visit to the Bhandup Water Treatment Plant was organized as part of the Environmental Engineering (CEC604) curriculum for Third Year Civil Engineering under the University of Mumbai.

Mumbai’s water supply comes from Upper Vaitarna, Middle Vaitarna, Modak Sagar, Tansa, Vehar, Tulsi Lakes, and Bhatsa River, and is treated at major plants located at Bhandup Complex, Panjarapur, Vehar, and Tulsi.

The Bhandup Complex has two major treatment plants:

Old Plant → Capacity of 1910 ML/day (+10% overload)

New Plant (commissioned 2014) → Capacity of 900 ML/day (+10% overload)

Thus, the combined treatment capacity is 2810 ML/day (+10% overload), making it one of the largest water treatment plants in Asia.

Raw water is received from Upper Vaitarna (108”), Vaitarna (96”), Tansa East (72”), and Tansa West (72”) mains through a 5.5 m diameter underground tunnel from Gundavali to the inlet bay of Bhandup Complex. The raw water undergoes a series of treatments to remove impurities and is processed to meet potable water standards, ensuring safe supply for millions of citizens in Mumbai.

| Name of the Event : | Colaba Sewage Treatment Plant Visit |

| Date & Time: | 11/03/2025 |

| Location : | Colaba, Mumbai |

| Staff Co-ordinator : | Prof. Pushkar Bharambe |

Acknowledgement :

We are gladly thankful to Prof. Pushkar Bharambe as well as Head of the Department, Dr. Ajit Patil Sir, who gave us great guidance regarding this training. A site visit was arranged to the Colaba Sewage Treatment Plant situated at Colaba.

Our main purpose for this visit was to get practical knowledge about the wastewater treatment plant process. By this visit, we became familiar with the industrial environment and gained knowledge about different units of a wastewater treatment plant. This experience will be especially useful in the upcoming subject Solid Waste Management, where understanding the working components of sewage plants is essential.

Focus Area :

The Colaba Sewage Treatment Plant (STP) in Mumbai, operational since April 2020, has a capacity of 37 million liters per day (MLD). Currently, the treated water is released into the sea via a 1.5 km pipeline. The Brihanmumbai Municipal Corporation (BMC) is exploring options to repurpose this treated water for non-potable applications such as gardening, road cleaning, and vehicle washing.

In a move towards water sustainability, the BMC is upgrading the Colaba STP to an Advanced Tertiary Treatment Plant (ATTP). This initiative aims to further treat sewage to make it suitable for potable use. The project includes the construction of a 12 MLD full-scale ATTP and a 0.1 MLD pilot facility mounted on a trailer, designed for mobility to different wastewater treatment sites in Mumbai.

The ATTP will employ a multi-barrier approach, incorporating processes such as:

Ozone Treatment

Granular Activated Carbon / Biological Activated Carbon Filtration

Ultra Filtration

Reverse Osmosis

Ultraviolet Disinfection (with or without Advanced Oxidation Process)

Remineralization with Chlorine for residual management

This project is part of Mumbai’s broader strategy to diversify its water sources and address the challenges posed by climate change and population growth.

Process Observed :

During the visit, students studied the following stepwise treatment processes:

Screening: Removal of large objects (plastics, diapers, rags, sanitary items, face wipes, broken bottles, etc.) that may damage equipment.

Primary Treatment: Wastewater is collected in large tanks where solid matter settles; scrapers remove sludge from the tank surface.

Secondary Treatment: Water is transported to the clarifier where lime and alum are added to reduce pH levels.

Aeration Tank: Air is blown into the liquid to provide oxygen and promote microbial growth in the activated sludge process. Some sludge is recycled back, while the rest is pumped for further treatment.

Disinfection Unit: Chlorine and other methods are used to reduce pathogens harmful to human health.

Sludge Digestion: Residual sludge is treated in a belt filter press, and water is further disinfected with chlorine.

Conclusion :

From this visit, we gained valuable practical knowledge about wastewater treatment processes and the functioning of different plant components. The detailed observation of each treatment stage enhanced our understanding of real-time wastewater management, bridging the gap between theoretical learning and industrial practice.

| Name of the Event : | NESCO Bombay Exhibition |

| Date &Time: | 30th September 2022 |

| Location : | Goregaon (E) |

| Staff Co-ordinator : | Mrs.Prajakta Mukadam, Mrs.Archana Mali, Mr.Pushkar Bharambe, Mr.Wasim Shaikh |

And with this, the visit was ended and a group photo was taken. Executive then gave some extra general knowledge about various processes and the session ended on a good note.

And with this, the visit was ended and a group photo was taken. Executive then gave some extra general knowledge about various processes and the session ended on a good note.| Name of the Event : | Traffic Volume Study |

| Date &Time: | 1st October 2022 |

| Venue– | Kashimira Square |

| No ofparticipants: | 45 |

| Platform/Mode: | Offline |

| Faculty In-charge: | Ms. Radhika Thakare |

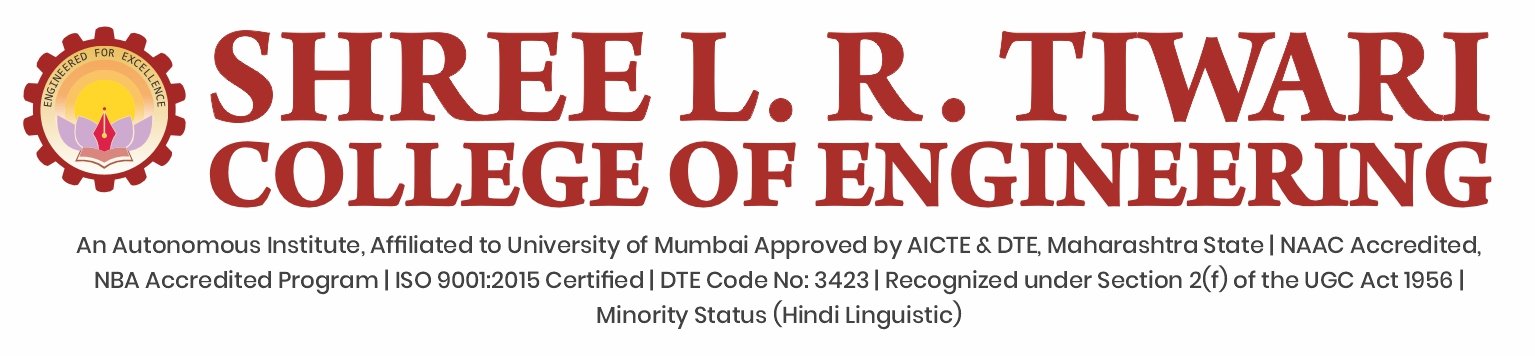

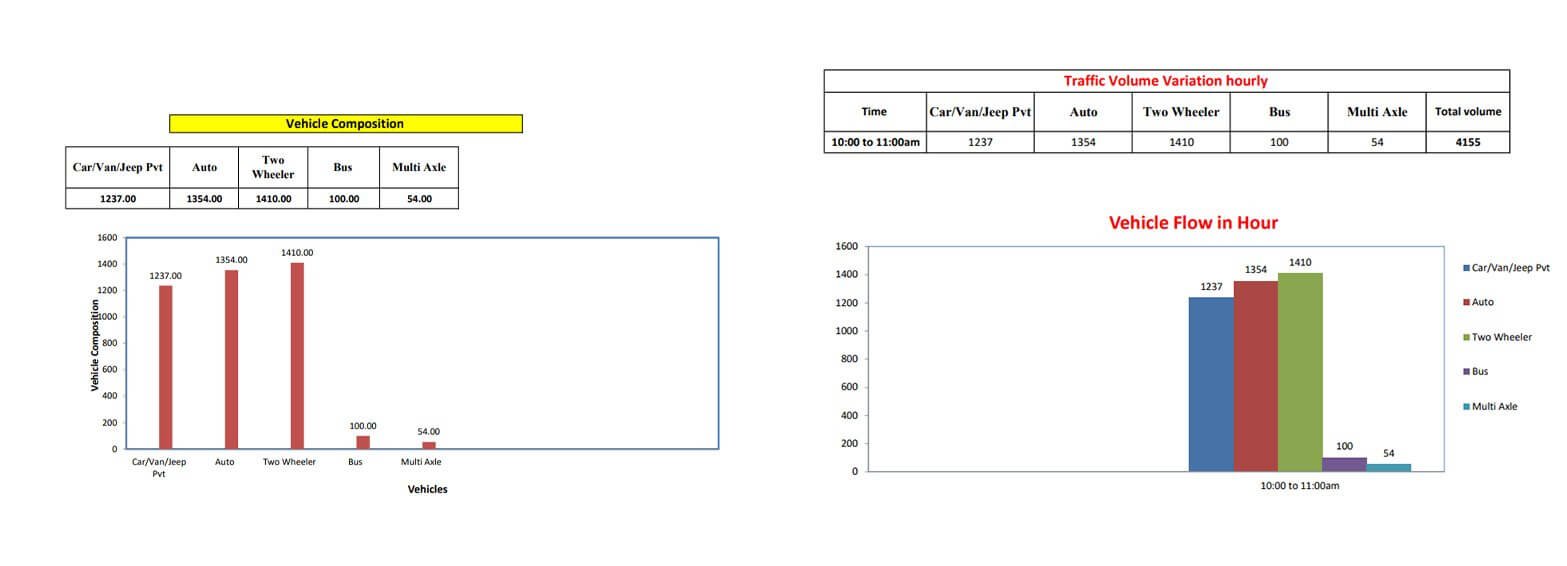

The Traffic Volume Study was conducted on October 1, 2022 as part of the Transportation Lab Syllabus for the TE Civil Engineering program at the University of Mumbai.

The Kashimira Square Site was selected for the study and students counted six different types of vehicles during the survey.

RESULT:

| Event Details | Duration | Venue | Participants |

| Industrial Visit conducted by Shree L R Tiwari College of Engineering for Second year & Third year students of Computer, IT, EXTE, ETRX, Civil & Mechanical department. | 12th January to 22th January, 2020 | Chandigarh-Kullu-Manali-Kasol-Dalhousie-Khajjar-Amritsar | Principal, Faculties, Staff, Students |

Objectives: The IV was organized to help students in developing them as competent professional with a sense of responsibility and social sensitivity.

IV has imparted professional education using active learning techniques to transform the students to be competent and committed engineers meeting the current and future demands.

- Staff Involved:

- Dr. S. Ram Reddy – Principal

- Mr. Pravin Jangid- Faculty in charge

- Organizing Core Committee

| Sr.No. | Name of Faculty/ staff/ Students | Committee | Responsibilities |

| 1 | Mr. Pravin Jangid | Overall Coordinator |

|

| 2 | Mr. Aditya Desai | SLRTCE Faculty incharge |

|

| 3 | Mr. AbhijIt Samanta | Coordinator |

|

| 4 | Ms. Shweta Chawhan | Coordinator |

|

| 5 | Mr. Sunny Sall | Coordinator |

|

| 6 | Pankaj Jadhav | Coordinator |

|

| 7 |

| Student coordinator |

|

Planning

- On August 18th, Principal took meeting all Faculty in charge of all department in Faculty reading regarding industrial. Mr. Pravin Jangid AP, CMPN was allocated duty of getting tour operator.

- On August 27th Comparative was given to Principal Sir, on basis of which Khushi Holiday Pvt ltd was chosen each was divided 4 industrial visit.

- On October 4th planning draft was forwarded by Mr. Pravin Jangid for approval of industrial on basis of which Money collection and other process were started.

- On January 2nd Principal called for a meeting of all the 7 Core committee along with the respective faculty accompanying the students to IV.

- Dr. S. Ram Reddy reminded every faculty members and students about collecting the thanks letter and mometo from college.

- He told that the students must follow the rules and regulations of the visitng industry in formals.

- Faculty member was asked to update Mr. Pravin Jangid or Principal Sir about the progress

Conduct: Participant’s details

| Designation | No of members |

| First Year Students | 25 |

| Second Year Students | 29 |

| Third Year Students | 66 |

| Faculty | 06 |

| Total | 126 |

THE BACKGROUND

During the month of July, our faculty in-charge Prof. Pravin Jangid informed us that we have to conduct an Industrial Visit during the semester breaks so that students can get an opportunity to learn about the organizations, system and performance. To have some live and practical knowledge about process and production in the industries.

Accordingly, with the guidance of, our principal Dr. S. Ram Reddy, our faculty in-charge Prof. Pravin Jangid and feedback from the faculties of SLRTCE, we finalized a 9-day industrial visit tour to Chandigarh-Kullu-Manali-Kasol-Dalhousie-Khajjar-Amritsar.

The tour details were handled by the core committee of SLRTCE and accordingly 120 students registered to take part in the 9-day tour.

The tour was finalized from the dates 12th January to 22th January, 2020. The total tour cost (inclusive of all taxes) came to Rs. 12,500/- per student.

| Sr.No. | Date | Description |

| Day 1 | 12th January 2020 |

|

| Day 2 | 13th January 2020 |

|

| Day 3 | 14th January, 2020 |

|

| Day 4 | 15th January 2020 |

|

| Day 5 | 16th January 2020 |

|

| Day 6 | 17th January 2020 | Early departure for jungle safari. |

| Day 7 | 18th January 2020 | On 7th day of our IV, Morning we had breakfast and after that we went to visit Khajjiar. Also visited Rock Garden. Afternoon spent in Khajjiar.Left for Amritsar and Reached hotel at night, had dinner. Overnight in hotel. |

| Day 8 | 19th January 2020 |

|

| Day 9 | 22th January 2018 |

|

| Sr.No. | Strength | Weakness | Opportunity | Threats |

| 1 | Arranged the industrial visit successfully.Shows leadership and decision making Qualities of students as they have to manage on their own without family pampering. | As the students were in large number, it is difficult to manage students on time | The knowledge gained can be used to understand processes thoroughly. | Name of industries were not disclosed prior. |

| 2 | Team work of faculty and core committee. Improves the on spot decision making at some instantaneous situations. | As student being on their fun Trip , getting them out from certain places becomes difficult | IV has given a new direction to the way of thinking to the students | Expectations were high of third year students due to previous IV |

| 3 | Effective communication between the students and faculty and among students too. | If any last minute change in itinerary or schedule due to environmental changes affects the connecting schedules | Students can now visualize the equipment’s which will be encountered during the academics | Environmental or climatic changes cannot be predicted |

| 4 | Effective follow up was done by faculty, coordinators and HoDs for more participation | Some cancellation and additions of student at last moments changes the schedule. | Quality interaction between student and industrial executive. | Some time Students behave unmannered in industries. |

Learning

Planned learning during the Industrial Visit

SLRTCE Students’ Chapter organized the industrial visit with an intention to provide students an edge of industrial environment and its proceeding. Following are some of the core principles and knowledge which was intended to impart into the participating students:

- Fraternity: Students of different branches were taken together and were managing things together thus developing social qualities. They had their own beliefs, intelligence, faith and even religions. With lots of diversity in their thinking and ideas all the students enjoyed at same place by doing same thing. Students made new friends from different department thus breaking the ice between departmental

- Industrial Procedures: Visiting industries of different sectors, different in operation, product, vision, mission etc. gave students the knowledge of corporate world.

- Improved way of learning: Students learned industrial mass production and the advanced technologies involved in it apart from their syllabus and prescribed practical during their academic curriculum, this industrial visit made them think in other way

Outcome

Students build many qualities in them after the Industrial Visit

- Friendship and feel of belonging: As the students were staying together throughout the trip they developed a sense of unity and compatibility amongst them.

- Practical Knowledge: Students witnessed the industrial conditions of the place where they might work in They got to know how an industry works and what all things they need to be prepared when they enter in corporate world.

- New edge to learning: The students during their academics hardly get time to explode beyond their syllabus but due to an exposer of such IVs they developed a new edge in their learning process. Students started thinking that the processes and other fact that they study are much lagging with current scenario and they need to enhance their cone of learning so that they can be industry

- A common platform for interaction of Student with industry experts provided fruitful interactions, inputs were provided by Company person regarding insight of industrial world.

Conclusion:

| Sr. No. | Session | Outcome |

| 1 | Finalization of Tour operator | Tour operator was finalized by Principal on basis of comparative submitted |

| 2 | Collection of instalment | Instalment was collected on basis of schedule displayed to student |

| 3 | Briefing | Briefing was done to all student on 31st December, 2017 and AICTE and college guideline was given to students |

| 5 | Industrial visit | Industry was shown to student which has fruitful interaction between company person and student and had insight about industry world |

| 6 | Final instalment | Final instalment was given after tour got over |

Learning:

- Through Industrial visit, we can provide an opportunity to current students to interact with person to know work culture in industry.

- Students know the techniques, skills, and modern engineering tools necessary for engineering practice

- Students uses the techniques, skills, and modern engineering tools necessary for engineering practice

- Student can get idea in industry environment which can use in R&D and E cell

Scope for Improvement:

- With changing trends and NBA requirement, such visit should be arranging for more number os students which can show overall development of students

- Industrial visit can be brought into the system through ISO & its implementation at department/section levels with the opportunities for corrective & preventive actions.

- Continuous communication system needs to be developed to make industrial visit a huge success

- Industry should be communicated through T&P to have better communication and timely confirmation

Testimonials

| A girl who is enjoying with her friends, making new friends, dancing, laughing till her stomach hurt. From train travels to hotels to unstoppable midnight chit-chats then from bus travels to talking about horror stories to playing games to eating street foods and traveling new beautiful places every moment was special. The day we reached back home we started thinking about planning another trip. We enjoyed it so much and had fun that we started missing those unforgettable days as soon as we reached home. We brought back memories that we will cherish for life. | Disha Parik (TE-CE) |

| Where we are exposed to workers who worked as professional and showed us the meaning of what a professional can do and since the IV was setup after our semester exam we got some time to relax and we really appreciate all the setup done by our college for the hotels and all the en-route and routine was managed very well and we enjoyed it a lot. I was so happy as the IV was totally worth the money and time and I will surely attend the next IV as well. | Tanmay Jadhav (TE-CE) |

| In all these years of my life perhaps I have never lived and loved life to the extent as this memorable trip. It has been an outstanding experience altogether where I got to know my friends and developed a charismatic affection towards them and life. All I can say is that if you all wish to explore and live life the magical way then definitely pack your bags and go on with a trip with buddies like uh. Still remember those sleepless nights and all the memories we made. | Ankush Nirala (SE – CE) |